Smart Manufacturing: Harnessing the Power of Industrial IoT

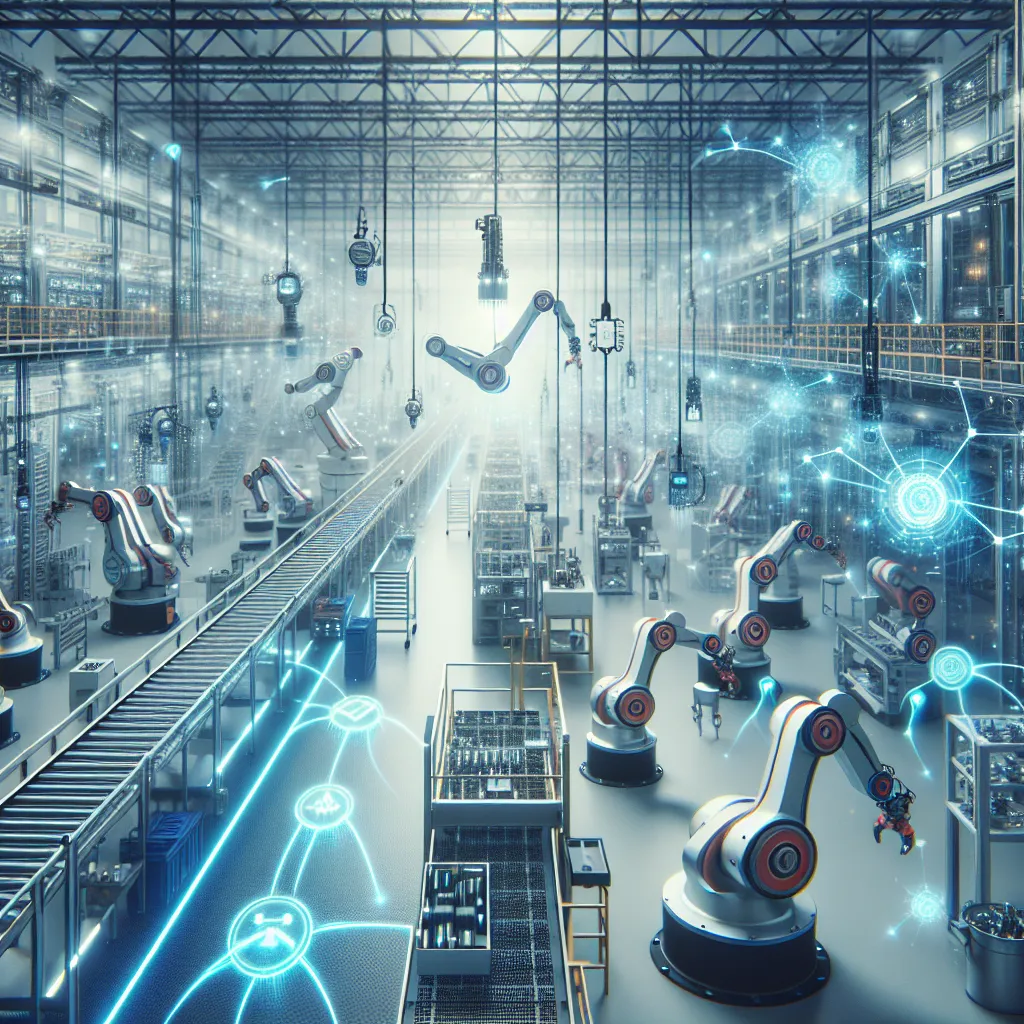

Smart Manufacturing, with its focus on harnessing the power of Industrial IoT (Internet of Things), has emerged as a transformative force in revolutionizing industrial efficiency. This cutting-edge approach leverages interconnected sensors, devices, and data analytics to optimize the manufacturing processes and enhance overall productivity. By integrating IoT technologies into industrial operations, businesses can gain real-time insights into their production systems, enabling proactive decision-making and predictive maintenance. The seamless connectivity facilitated by Industrial IoT facilitates the exchange of data across the manufacturing ecosystem, thus enabling intelligent automation and resource optimization.

Advancements in Robotics and Automation for Enhanced Productivity

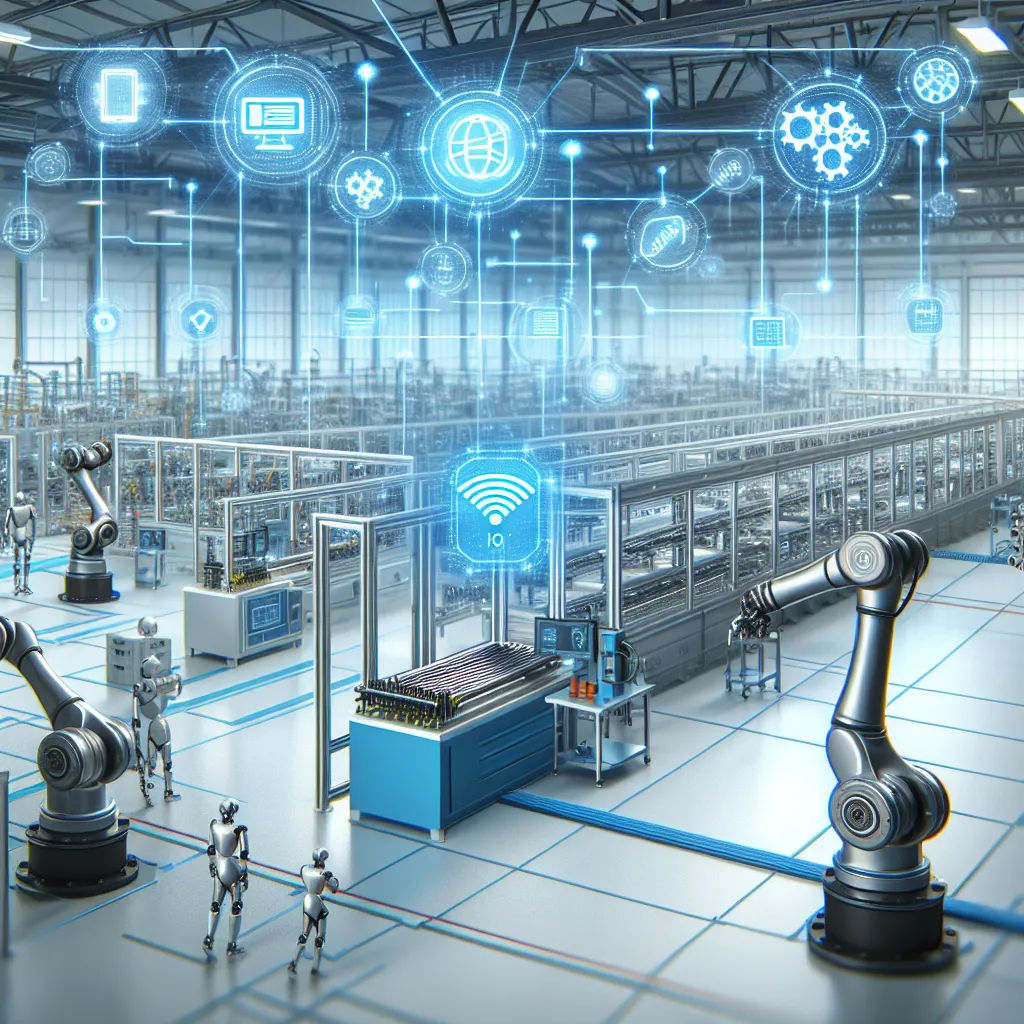

Advancements in robotics and automation have been pivotal in revolutionizing industrial efficiency and enhancing productivity. With the integration of cutting-edge robotic technology and automation systems, industries are experiencing substantial improvements in production processes and overall operational efficiency.

The utilization of robotics in industrial manufacturing has significantly streamlined operations by performing repetitive tasks with precision and consistency. Robots equipped with advanced sensors and machine learning algorithms can adapt to different variables in the production environment, ensuring high-quality output while minimizing errors and waste.

Furthermore, automation solutions have played a crucial role in optimizing productivity by orchestrating seamless coordination between various stages of production. Automated systems can efficiently manage inventory, handle material transportation, and oversee assembly processes, leading to efficient resource utilization and reduced downtimes.

The integration of robotics and automation has also enhanced workplace safety by delegating hazardous tasks to robotic systems, thereby minimizing the risk of workplace accidents and ensuring a safer working environment for employees.

Overall, the advancements in robotics and automation technologies are driving a paradigm shift in industrial efficiency, providing companies with the tools to optimize productivity, improve product quality, and maintain a competitive edge in the global market.

Utilizing Data Analytics to Optimize Industrial Processes

Data analytics is revolutionizing industrial efficiency by providing cutting-edge solutions to optimize industrial processes. By utilizing advanced data analytics tools, industrial companies can gain valuable insights into their operations, leading to improved productivity, cost savings, and overall performance. With the massive amount of data generated in industrial settings, harnessing this data effectively can lead to significant competitive advantages.

One of the key aspects of utilizing data analytics in industrial processes is the ability to gather and analyze real-time data from sensors and connected devices. This real-time monitoring allows for quick identification of inefficiencies or potential issues, enabling proactive decision-making and rapid adjustments to optimize production processes.

Furthermore, predictive analytics plays a crucial role in anticipating maintenance needs and identifying potential equipment failures before they occur. By implementing predictive maintenance strategies based on data analytics, industrial companies can significantly reduce downtime, enhance equipment reliability, and extend the lifespan of their assets.

Another important application of data analytics in industrial efficiency is the optimization of supply chain management. By analyzing data related to inventory levels, demand forecasting, and supplier performance, companies can make informed decisions to streamline their supply chain, reduce inventory costs, and improve overall operational efficiency.

In conclusion, the utilization of data analytics is a game-changer in revolutionizing industrial efficiency. By leveraging cutting-edge data analytics solutions, industrial companies can unlock the full potential of their operations, drive continuous improvements, and stay ahead in today’s competitive marketplace.