The Integration of AI and Robotics in Industrial Processes

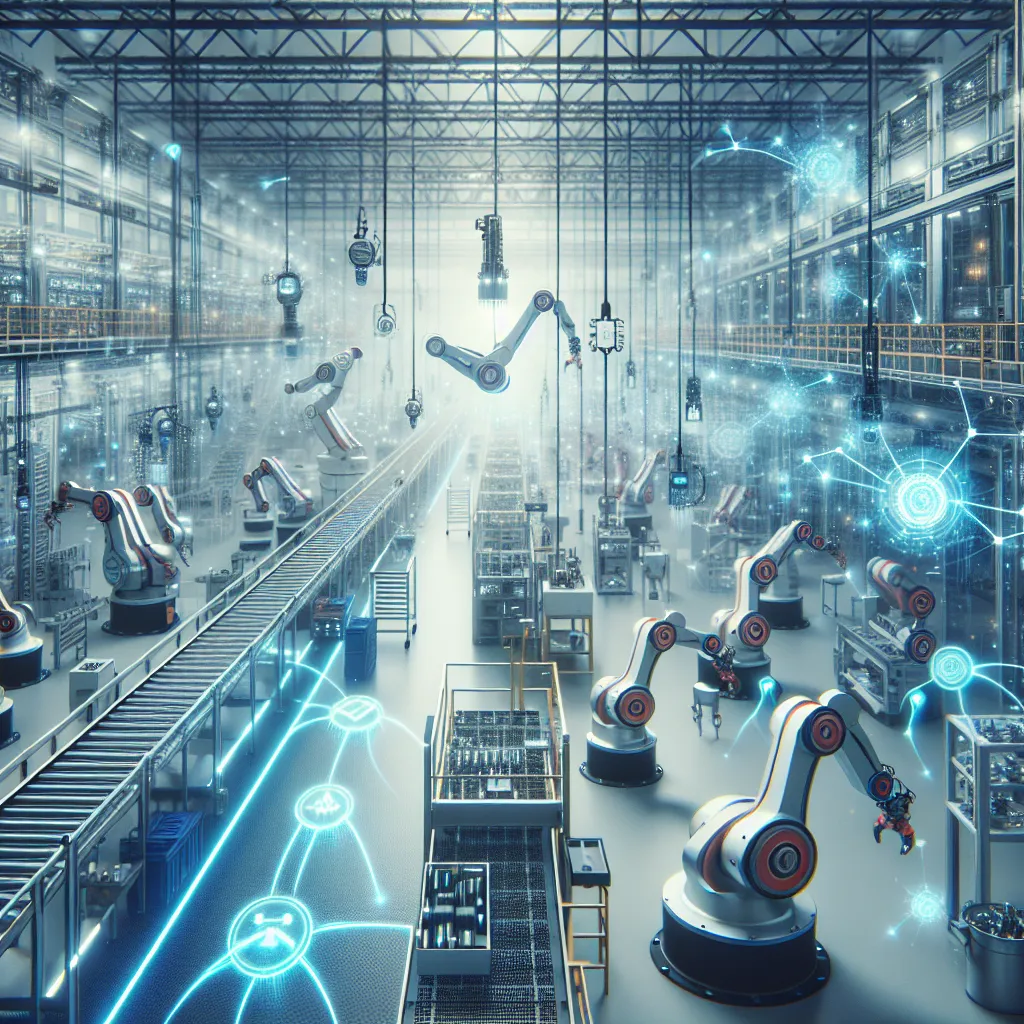

One of the most significant advancements in modern industrial solutions is the integration of artificial intelligence (AI) and robotics in industrial processes. This innovative integration has revolutionized the way manufacturing and production facilities operate, offering unparalleled efficiency, precision, and flexibility.

AI plays a pivotal role in industrial automation by enabling machines to analyze data, make decisions, and adapt to changing conditions in real time. This capability significantly enhances the efficiency and productivity of industrial processes, leading to reduced downtime, optimized resource utilization, and improved quality control. Moreover, AI-powered predictive maintenance systems can anticipate equipment failures, allowing for proactive maintenance and minimizing costly disruptions.

Complementing AI, robotics has transformed industrial operations by automating repetitive tasks, handling complex manipulations, and ensuring consistent output quality. The integration of AI and robotics has enabled the development of versatile, adaptive robotic systems that can collaborate with human workers, further enhancing productivity and workplace safety. Collaborative robots, or “cobots,” are designed to work alongside human operators, streamlining tasks that require precision and dexterity while reducing the risk of workplace accidents.

Furthermore, the combination of AI and robotics has facilitated the implementation of smart manufacturing processes, where interconnected systems communicate and optimize production flows in real time. This interconnectedness, often referred to as the Industrial Internet of Things (IIoT), enables seamless coordination between machines, enabling agile responses to changes in demand, supply chain dynamics, and production parameters.

In conclusion, the integration of AI and robotics in industrial processes represents a transformative leap towards efficient, adaptive, and intelligent manufacturing solutions. As technological advancements continue to evolve, the synergy between AI and robotics will undoubtedly drive further innovation, shaping the future of industrial production.

Optimizing Efficiency Through IoT in Industrial Solutions

One of the key aspects of modern industrial solutions is the utilization of technology to optimize efficiency. In this context, the Internet of Things (IoT) plays a pivotal role in revolutionizing industrial processes. By integrating IoT devices and sensors into various machinery and equipment, industries can gather real-time data and insights into their operations, leading to significant improvements in efficiency and productivity.

IoT enables industrial solutions to achieve proactive maintenance by constantly monitoring the performance of equipment. This not only reduces the likelihood of unexpected downtimes but also allows for predictive maintenance, thereby preventing potential failures before they occur. As a result, businesses can save on maintenance costs and ensure continuous operation without disruption.

Furthermore, the data collected through IoT devices can be leveraged for process optimization. By analyzing the performance metrics and patterns, industrial facilities can identify bottlenecks, streamline workflows, and make data-driven decisions to enhance overall efficiency. This level of insight into operational processes empowers businesses to drive continuous improvement and adapt quickly to changing demands in the market.

Through IoT in industrial solutions, real-time tracking of inventory, equipment status, and production metrics becomes feasible. This transparency in data empowers businesses to make informed decisions to minimize waste, reduce inventory holding costs, and optimize resource allocation. Moreover, IoT-enabled systems can facilitate coordination among different stages of production, leading to synchronized and efficient operations.

In conclusion, the integration of IoT in modern industrial solutions is instrumental in optimizing efficiency, reducing downtime, enabling proactive maintenance, and providing invaluable data-driven insights for continuous improvement. As technology continues to advance, harnessing the power of IoT will undoubtedly be a key differentiator for industrial businesses seeking to remain competitive in the ever-evolving landscape of manufacturing and production.

Sustainable Manufacturing Practices: The Impact of Technology

Technology plays a crucial role in driving sustainable manufacturing practices in modern industrial solutions. The impact of technology on sustainable manufacturing practices is profound, with advancements revolutionizing the way industries operate and significantly reducing their environmental footprint. One of the key aspects of technology’s influence on sustainable manufacturing is the integration of smart and automated systems. These systems optimize energy usage, reduce waste, and enhance overall production efficiency. Additionally, the implementation of data analytics and machine learning algorithms enables real-time monitoring and predictive maintenance, further minimizing resource wastage and maximizing equipment lifespan.

Furthermore, the emergence of additive manufacturing, also known as 3D printing, has opened up new avenues for sustainable production. This technology enables the creation of complex, lightweight designs with minimal material waste, offering a viable solution for eco-friendly manufacturing. Moreover, the adoption of renewable energy sources, such as solar and wind power, supported by technological developments, has significantly reduced the carbon footprint of industrial operations.

Another noteworthy impact is the incorporation of Internet of Things (IoT) devices, which facilitate the seamless integration of equipment and processes, leading to optimized resource utilization and streamlined production flows. These interconnected systems provide valuable insights into energy consumption patterns and production inefficiencies, allowing for targeted improvements in sustainability efforts. The role of technology in sustainable manufacturing practices is paramount, driving continuous innovation and pushing industries towards environmentally conscious and sustainable operational models.