Revolutionizing Efficiency: Streamlined Industrial Production with Advanced Technologies

In the quest for maximizing output, industries are constantly seeking innovative solutions to revolutionize efficiency and streamline production processes. Advanced technologies have played a pivotal role in this endeavor, enabling industrial facilities to achieve unprecedented levels of productivity while reducing costs and minimizing waste.

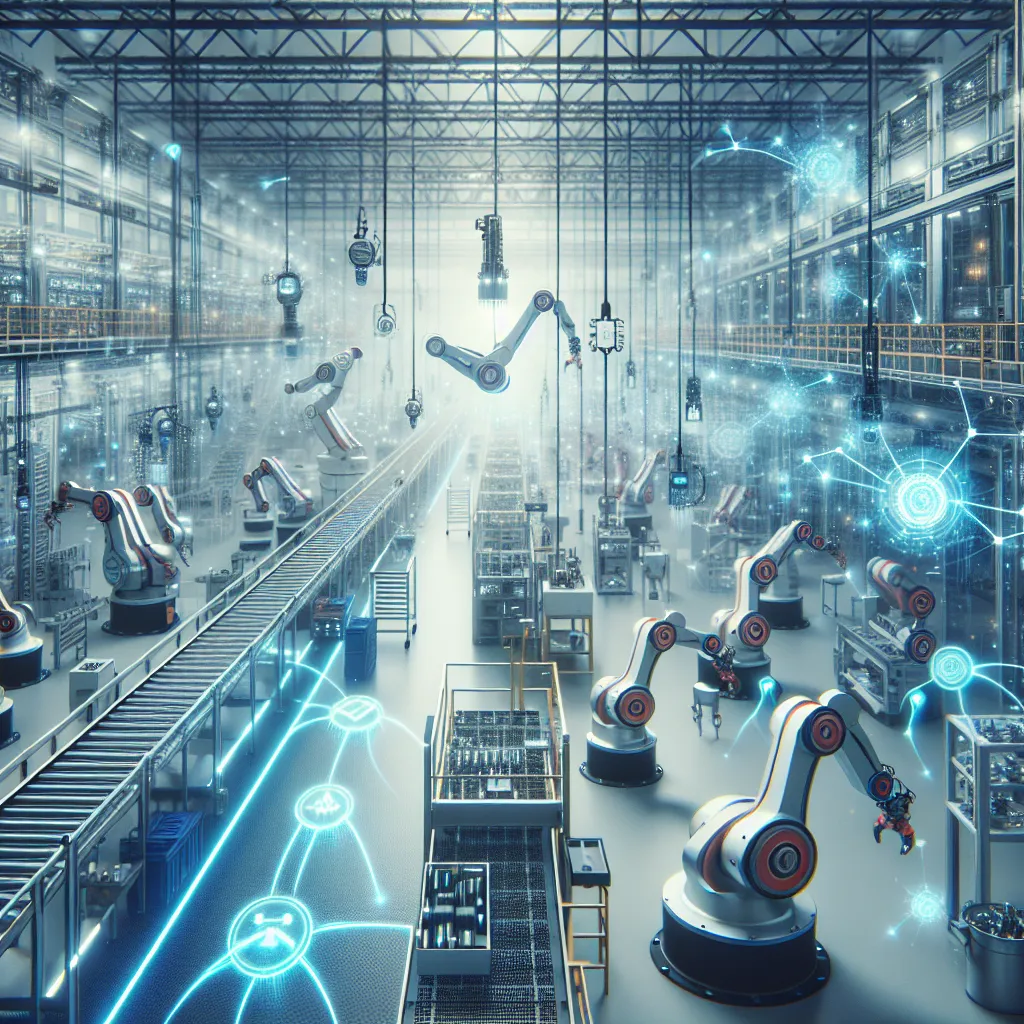

One of the key advancements revolutionizing efficiency in industrial production is the integration of smart manufacturing systems. These systems leverage the power of connected devices, real-time data analytics, and automation to optimize the entire production lifecycle. By implementing sensors and actuators across the production line, manufacturers can gather valuable insights into machine performance, predictive maintenance requirements, and overall process efficiency.

Furthermore, the adoption of advanced robotics and artificial intelligence (AI) has significantly transformed industrial production. Robotic systems equipped with AI capabilities are capable of handling complex tasks with precision and speed, leading to enhanced productivity and consistently high output quality. AI algorithms also empower manufacturers to forecast demand, adjust production schedules dynamically, and optimize resource utilization, thereby maximizing output while minimizing downtime.

Another pivotal aspect of revolutionizing efficiency in industrial production is the deployment of additive manufacturing, commonly known as 3D printing. This breakthrough technology enables manufacturers to produce intricate parts and components with unparalleled precision, thereby reducing material wastage and accelerating prototyping and production processes. Additionally, the flexibility offered by 3D printing allows for on-demand manufacturing, customization of products, and rapid iterations, all contributing to increased output efficiency.

In conclusion, by embracing these advanced technologies, industrial facilities can effectively streamline production processes, maximize output, and gain a competitive edge in today’s dynamic market landscape. As the industrial sector continues to evolve, the innovative integration of smart manufacturing, robotics, AI, and additive manufacturing will undoubtedly play a central role in driving efficiency and productivity to new heights.

Breaking Boundaries: Cutting-Edge Strategies for Maximizing Industrial Output

In today’s competitive industrial landscape, maximizing output is a top priority for companies seeking to gain a leading edge in their respective sectors. Breaking boundaries and adopting cutting-edge strategies have become essential for achieving this goal. Innovations in industrial solutions have paved the way for unprecedented levels of productivity and efficiency.

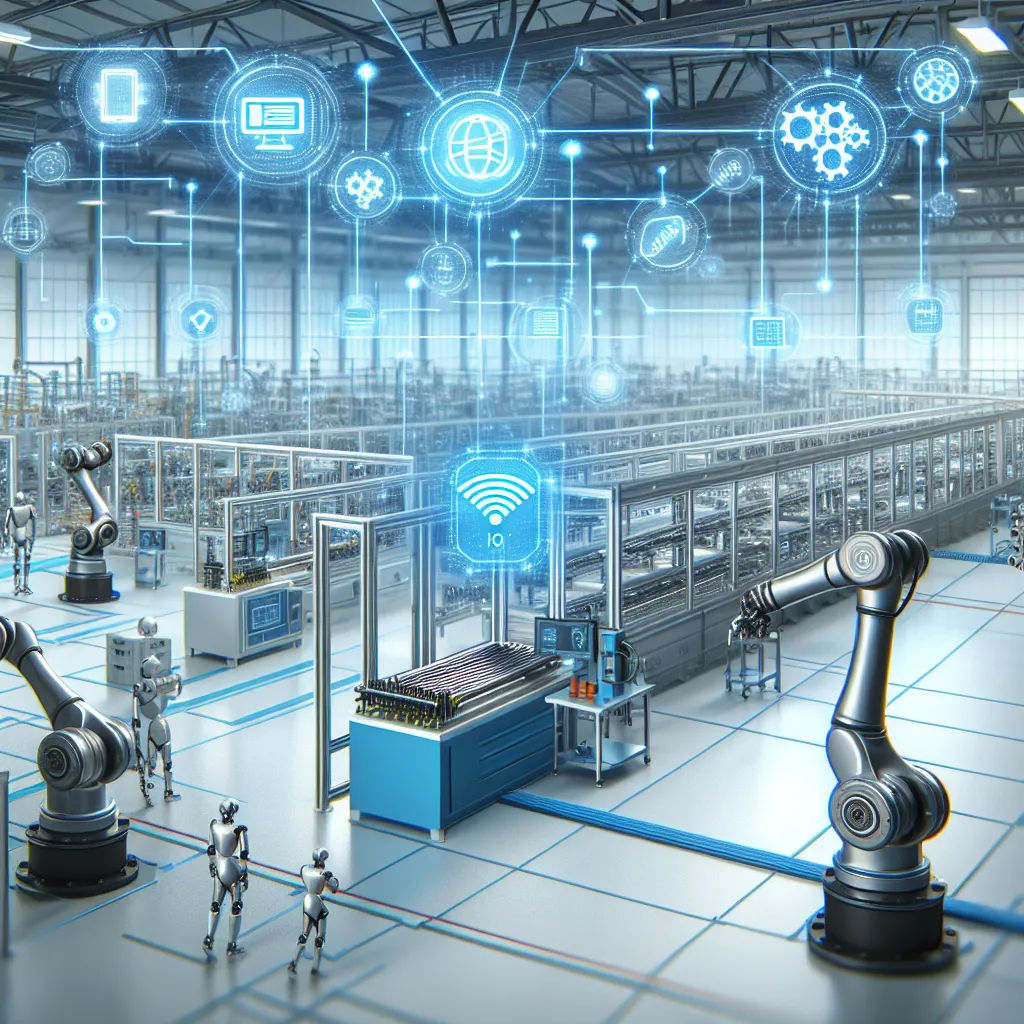

One of the key strategies for maximizing industrial output is the integration of advanced automation technologies. This includes the implementation of robotic systems, AI-driven processes, and IoT-enabled machinery. These technologies not only streamline production processes but also enable real-time monitoring and predictive maintenance, minimizing downtime and maximizing overall output.

Furthermore, the concept of breaking boundaries in industrial output encompasses the utilization of big data analytics. By harnessing the power of data, companies can gain invaluable insights into their operations, leading to optimized workflows, enhanced resource utilization, and the identification of potential inefficiencies.

Additionally, the adoption of additive manufacturing technologies has revolutionized production capabilities, allowing for highly complex and customized components to be fabricated with remarkable precision. This has significantly contributed to increasing output while reducing lead times and material waste.

In conclusion, breaking boundaries and leveraging cutting-edge strategies are pivotal in maximizing industrial output. By embracing innovation and integrating advanced technologies, companies can unlock new levels of productivity, efficiency, and competitiveness in today’s dynamic industrial landscape.

Unleashing Potential: The Future of Industrial Solutions and Output Optimization

When it comes to maximizing output in industrial solutions, innovation plays a crucial role in unleashing the full potential of production processes. The future of industrial solutions and output optimization lies in leveraging cutting-edge technologies and advanced methodologies to achieve higher efficiency, lower costs, and reduced environmental impact.

One of the key areas where innovation is driving significant advancements is in the realm of automation. The integration of artificial intelligence, machine learning, and robotics is revolutionizing industrial processes, allowing for greater precision, consistency, and speed in production. This not only boosts output levels but also enhances overall quality.

Furthermore, the concept of smart factories is gaining traction as a means to maximize output. By interconnecting machinery, devices, and sensors through the Internet of Things (IoT), manufacturers can collect and analyze real-time data to optimize operations, predict maintenance needs, and minimize downtime, thereby maximizing productivity.

In addition to technological innovations, the future of industrial solutions also entails a shift towards sustainable practices. Implementing eco-friendly initiatives, such as renewable energy sources, energy-efficient machinery, and waste reduction strategies, not only aligns with environmental goals but also leads to cost savings and improved output efficiency.

In conclusion, the future of industrial solutions and output optimization is intertwined with continuous innovation, integrating advanced technologies, and embracing sustainable practices. By unleashing the potential of these advancements, manufacturers can maximize their output while operating efficiently and responsibly in an ever-evolving industrial landscape.