Advancements in AI and Machine Learning for Industrial Problem-Solving

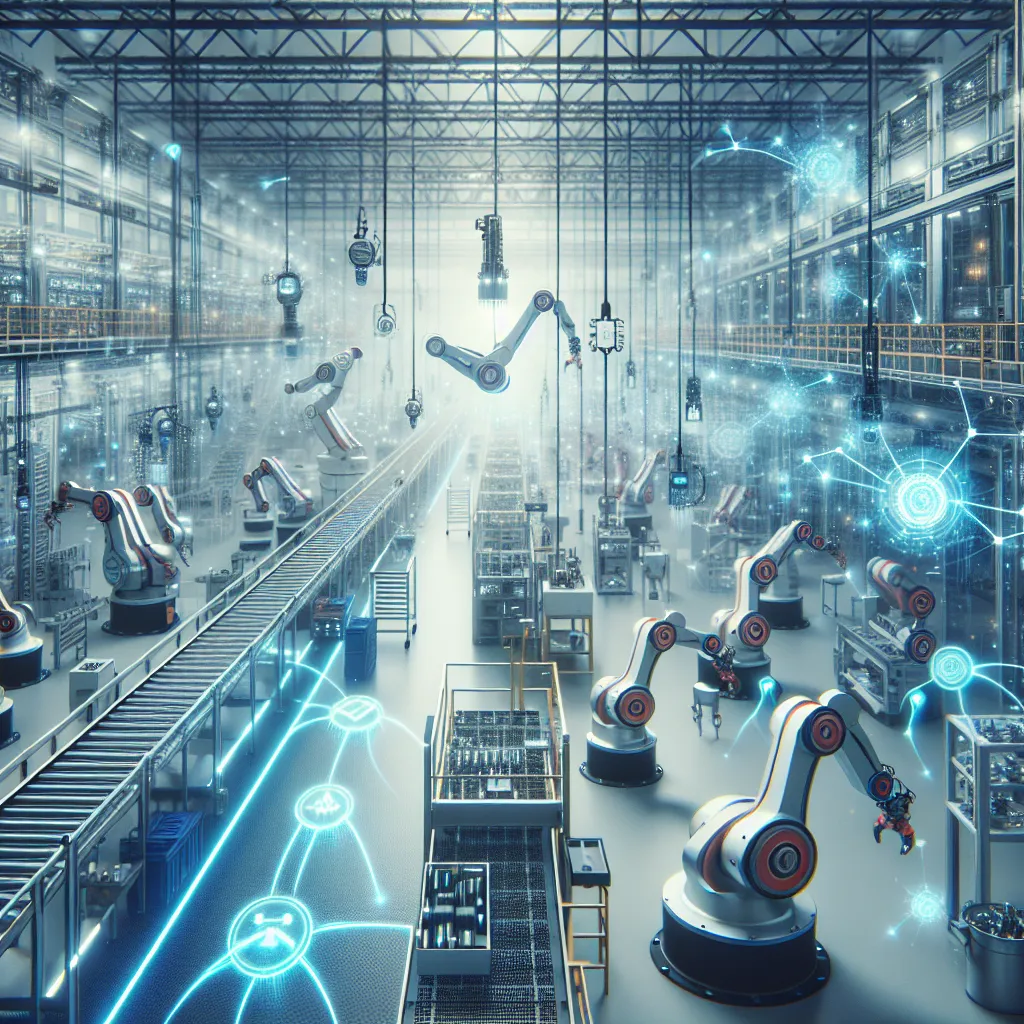

Advancements in AI and machine learning have revolutionized the industrial sector, offering innovative techniques for solving complex challenges. By harnessing the power of AI and machine learning algorithms, industries can significantly enhance their problem-solving capabilities and streamline operations.

One of the key applications of AI and machine learning in industry is predictive maintenance. By analyzing historical data and identifying patterns, these technologies can predict when industrial equipment is likely to fail, allowing for proactive maintenance and minimizing downtime. This not only reduces maintenance costs but also improves overall operational efficiency.

AI and machine learning are also being leveraged for quality control in manufacturing processes. These technologies can analyze vast amounts of data from production lines in real time, quickly detecting any deviations or defects. This proactive approach to quality control helps identify issues early, reducing rework and waste while ensuring that only high-quality products reach the market.

Furthermore, AI-powered optimization is transforming industrial operations by fine-tuning processes for maximum efficiency. Whether it’s resource allocation, supply chain management, or workflow optimization, AI and machine learning algorithms can identify opportunities for improvement and autonomously implement adjustments, leading to cost savings and improved productivity.

In conclusion, the advancements in AI and machine learning have brought about a paradigm shift in industrial problem-solving. By leveraging these innovative techniques, industries can proactively address challenges, optimize operations, and stay ahead in today’s competitive landscape.

Blockchain Applications Revolutionizing Industrial Operations

Blockchain technology has emerged as a groundbreaking innovation with the potential to revolutionize industrial operations across various sectors. By providing a secure and immutable platform for transactions and data exchange, blockchain applications are reshaping the way industries approach challenges related to transparency, security, and efficiency.

One of the key areas where blockchain is making a significant impact is supply chain management. The decentralized and tamper-proof nature of blockchain technology enables real-time tracking of goods and components as they move through the supply chain. This transparency not only minimizes the risk of counterfeit products but also enhances the overall efficiency of the supply chain.

Moreover, blockchain applications are streamlining the process of contractual agreements and negotiations. Smart contracts, powered by blockchain technology, automate and enforce the terms of a contract, reducing the need for intermediaries and potentially minimizing disputes. This not only saves time and resources but also ensures a higher level of trust and security in business interactions.

Additionally, the integration of blockchain in the industrial IoT (Internet of Things) landscape is revolutionizing data management and security. With blockchain, IoT devices can securely record and store data, creating an immutable record of the device’s history and interactions. This enhances the reliability of IoT data, which is crucial for industries relying on accurate and secure data for their operations.

In conclusion, the application of blockchain technology is driving a paradigm shift in industrial operations, addressing challenges related to transparency, security, and efficiency. As industries continue to explore and implement blockchain solutions, the potential for further advancements and optimizations in industrial processes is substantial.

Smart Sensor Technology: Enhancing Industrial Efficiency

Smart sensor technology has revolutionized the industrial landscape by providing innovative solutions to age-old challenges. These advanced sensors are enhancing industrial efficiency by providing real-time data and insights into various processes, enabling proactive maintenance and optimization of operations. By leveraging smart sensor technology, industries can monitor equipment performance, detect anomalies, and prevent potential breakdowns, thus minimizing downtime and maximizing productivity.

One of the key advantages of smart sensor technology is its ability to facilitate predictive maintenance. By continuously monitoring equipment and capturing data on various parameters such as temperature, vibration, and energy consumption, these sensors enable early detection of potential issues, allowing for timely maintenance and preventing costly unplanned downtime. This proactive approach not only saves time and resources but also extends the lifespan of critical industrial assets.

Another significant aspect of smart sensor technology is its role in enabling condition-based monitoring. These sensors can provide insights into the current condition of machinery and infrastructure, allowing for data-driven decision-making. With the integration of IoT (Internet of Things) capabilities, smart sensors can communicate and collaborate with other connected devices, creating an interconnected ecosystem that streamlines industrial processes and enhances overall efficiency.

Furthermore, smart sensor technology plays a vital role in ensuring workplace safety and regulatory compliance. By monitoring environmental factors such as air quality, noise levels, and hazardous substance leaks, these sensors contribute to creating a safer work environment for industrial personnel. Moreover, the data collected by these sensors can aid in compliance with regulatory standards, providing valuable documentation of adherence to environmental and safety regulations.

In conclusion, smart sensor technology is a cornerstone of modern industrial efficiency, offering unparalleled insights and capabilities that enable proactive, data-driven decision-making. As industries continue to embrace digital transformation, smart sensors will play an increasingly crucial role in overcoming industrial challenges and driving sustainable growth.