The Impact of Robotics and AI on Industrial Efficiency

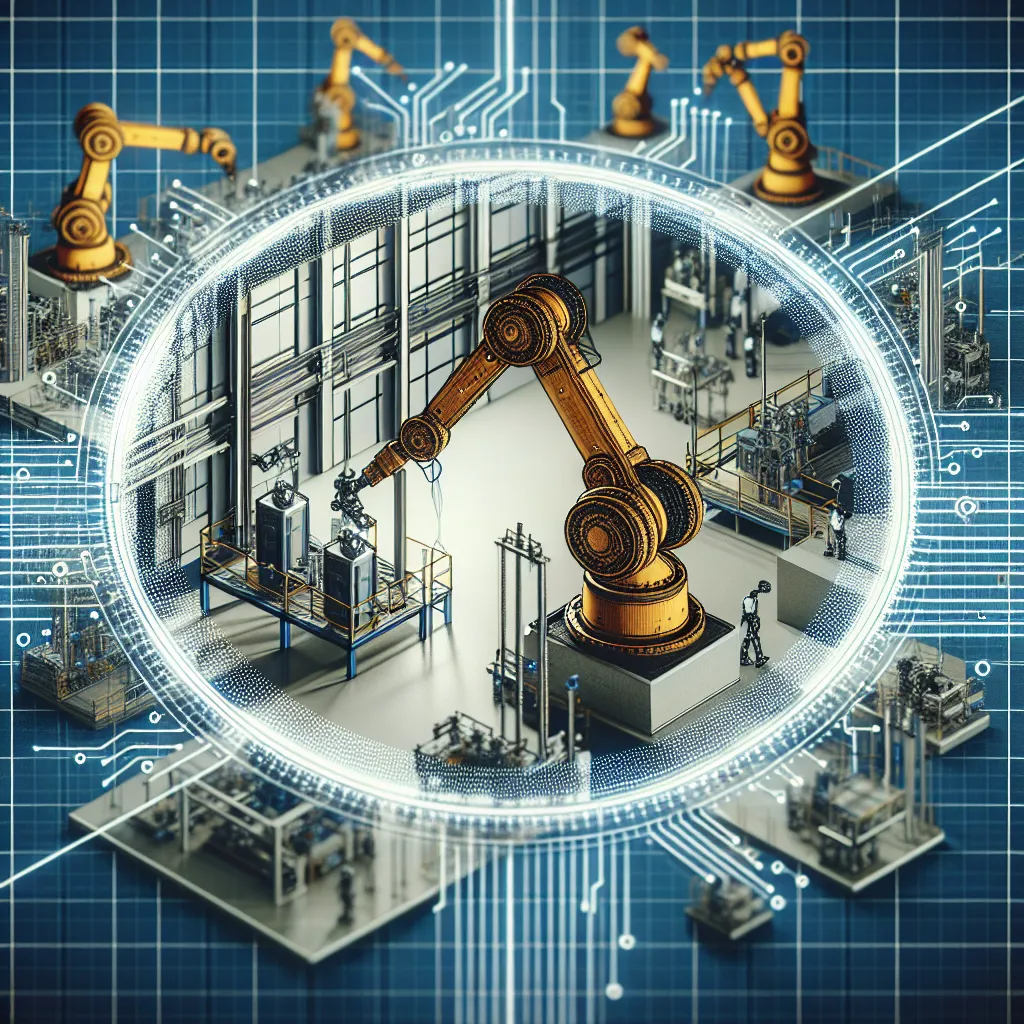

Advancements in automation technology have revolutionized industries across the globe, with robotics and artificial intelligence (AI) playing a pivotal role in transforming industrial efficiency. The integration of robotics and AI has significantly impacted manufacturing processes, leading to improved productivity, precision, and cost-effectiveness.

Robots equipped with AI capabilities have the capacity to perform complex tasks with a level of accuracy and consistency that surpasses human capabilities. This has led to a reduction in errors and defects, ultimately enhancing the overall quality of products. Additionally, the use of robotics and AI has streamlined production processes, resulting in increased efficiency and output.

Furthermore, the implementation of automation technology has enabled industries to optimize resource utilization and minimize waste. With the ability to operate 24/7, robots have facilitated continuous production cycles, contributing to a significant decrease in lead times and enhanced operational efficiency.

Moreover, the utilization of robotics and AI in industrial settings has had a positive impact on workplace safety. By handling hazardous tasks and operating in environments unsuitable for human workers, robots have helped reduce the risk of workplace accidents and injuries.

In conclusion, the integration of robotics and AI has brought about a paradigm shift in industrial efficiency, paving the way for enhanced productivity, precision, and safety across various sectors. As technology continues to advance, the potential for further optimization and innovation in industrial automation remains vast.

How Automation is Revolutionizing Manufacturing Processes

Advancements in automation technology have brought about a significant transformation in the manufacturing industry. This revolution is characterized by the integration of innovative automation systems that enhance efficiency, precision, and productivity in manufacturing processes. Automation technologies such as robotic arms, automated conveyors, and advanced control systems have redefined the way products are manufactured, assembled, and packaged.

The implementation of automation in manufacturing processes has led to a substantial reduction in production time and costs while improving the overall quality of the products. By utilizing automated systems for repetitive and labor-intensive tasks, manufacturers can achieve higher output levels and meet the increasing demands of the market. The precision and consistency offered by automation technology have minimized errors and defects, contributing to the production of superior goods.

Furthermore, automation has enabled manufacturers to adapt to rapidly changing consumer preferences and market dynamics. Advanced automation systems equipped with machine learning and artificial intelligence capabilities can analyze production data in real time, allowing for predictive maintenance, proactive decision-making, and seamless adaptability to varying production requirements. This agility is crucial in today’s competitive landscape, where rapid adaptation and flexibility are essential for success.

The integration of automation technology in manufacturing processes has not only optimized operational efficiency but also improved the overall workplace safety. By delegating hazardous tasks to automated systems, the risk of workplace accidents has been significantly reduced, creating a safer and more secure environment for the workforce.

In conclusion, the advancements in automation technology have revolutionized manufacturing processes by elevating productivity, quality, adaptability, and safety. As industries continue to embrace automation, the future of manufacturing is poised to be defined by unprecedented levels of efficiency and innovation.

Enhancing Productivity Through Automation Technology

Advancements in automation technology have revolutionized industries, enhancing productivity by streamlining processes and reducing human error. Automation technology, including robotics, artificial intelligence, and machine learning, has enabled companies to optimize their operations, leading to increased efficiency and output. By integrating automated systems into manufacturing, logistics, and other sectors, businesses have experienced significant improvements in speed, accuracy, and overall performance.

Automation technology has allowed for the elimination of repetitive and labor-intensive tasks, freeing up human resources to focus on more complex and creative endeavors. This shift has not only increased productivity but also improved job satisfaction and employee engagement. In addition, automation has facilitated the collection and analysis of large volumes of data, providing valuable insights for decision-making and process refinement.

Furthermore, the integration of automation technology has contributed to cost savings through reduced waste, optimized resource utilization, and minimized downtime. The implementation of smart, interconnected systems has also enabled real-time monitoring and predictive maintenance, ensuring continuous operations and avoiding costly disruptions.

As industries continue to harness the power of automation technology, the potential for further advancements and enhancements in productivity appears limitless. By embracing automation, businesses can stay competitive in an ever-evolving market, drive innovation, and achieve sustainable growth.