Implementing Automation in Warehouse Management

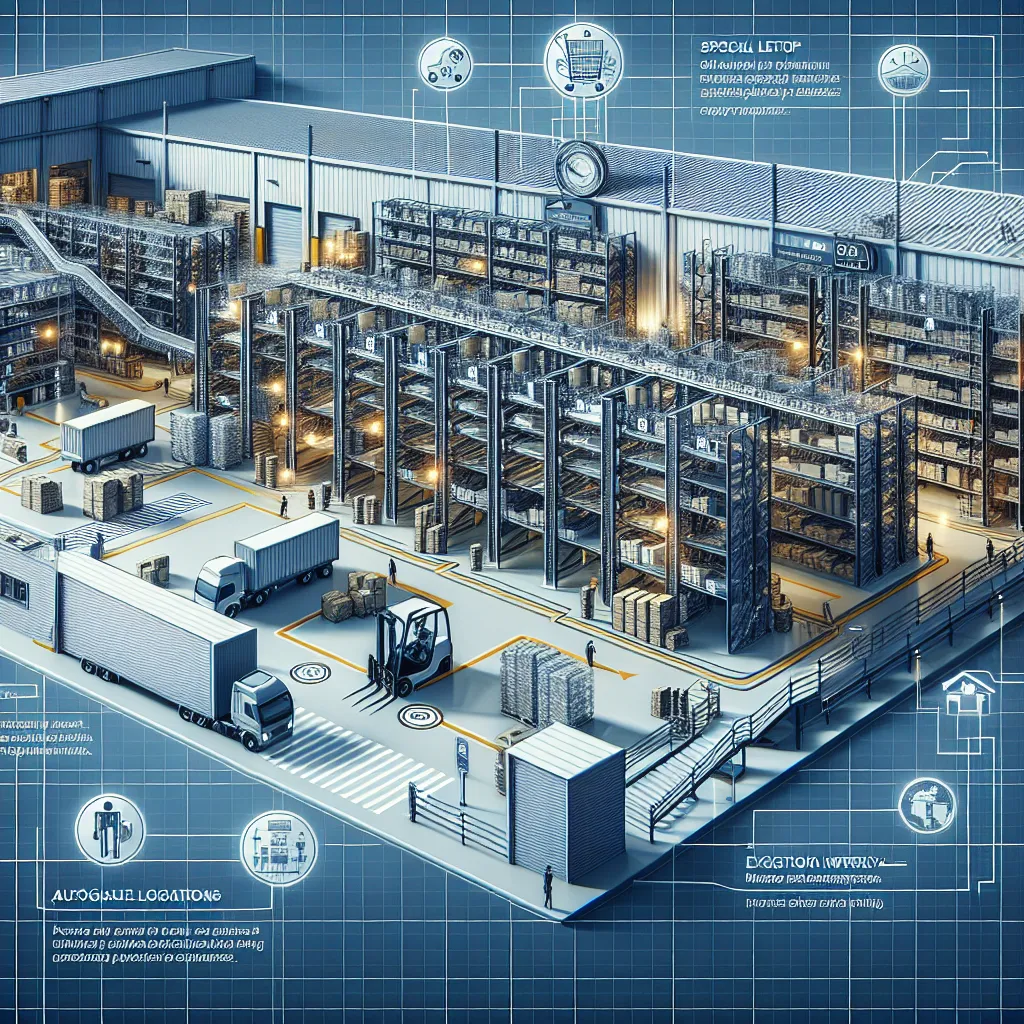

Implementing automation in warehouse management is a crucial aspect of optimizing logistics operations for efficiency and productivity. By utilizing automated technologies such as barcode scanning, RFID systems, and automated storage and retrieval systems (AS/RS), warehouses can significantly improve inventory accuracy, order fulfillment speed, and overall operational efficiency.

Barcode scanning technology enables quick and accurate data capture, allowing for real-time inventory tracking and management. RFID systems further enhance this capability by enabling the tracking of inventory items without line-of-sight requirements, thus streamlining the receiving, put-away, and picking processes.

Automated storage and retrieval systems (AS/RS) play a pivotal role in optimizing warehouse space and resources. These systems utilize advanced robotics and software to automate the process of storing and retrieving goods, maximizing the use of vertical space and reducing the need for manual intervention. This not only increases storage capacity but also enhances order fulfillment speed by providing rapid access to inventory items.

Furthermore, the implementation of automation in warehouse management can lead to significant cost savings in labor and operational expenses. By automating repetitive tasks such as inventory counting, data entry, and order picking, companies can reallocate human resources to more value-added activities while also reducing the likelihood of errors.

In conclusion, integrating automation into warehouse management is essential for streamlining logistics operations and achieving greater efficiency. By leveraging technologies such as barcode scanning, RFID systems, and AS/RS, companies can optimize inventory management, maximize space utilization, and reduce operational costs, ultimately gaining a competitive edge in today’s dynamic market.

Remember to include regular headings, and to break up your text with H2, H3, etc. Also include a sample meta description and some bullet points with relevant key phrases to complete your optimization for the search engine.

I hope this helps! Let me know if you need further assistance.

Streamlining Inventory Tracking Systems for Improved Logistics

Streamlining inventory tracking systems is crucial for achieving efficient logistics operations in a warehouse. By optimizing the process of tracking and managing inventory, businesses can significantly improve their overall operations and customer satisfaction. Implementing advanced technologies such as RFID systems, barcode scanning, and inventory management software can streamline the tracking of goods within the warehouse, providing real-time visibility and accuracy of inventory levels.

Utilizing RFID technology allows for automated, real-time tracking of inventory as it moves throughout the warehouse, enabling precise and efficient inventory management. This not only reduces the time and labor required for manual inventory counts but also minimizes the risk of errors and inaccuracies. Barcode scanning further enhances the tracking process by enabling quick and accurate identification of products, ensuring efficient picking, packing, and shipping processes.

Moreover, the integration of inventory management software provides comprehensive tools for monitoring and optimizing inventory levels, order fulfillment, and replenishment processes. These systems offer insights into demand patterns, stock movements, and order processing, enabling businesses to make data-driven decisions to improve overall efficiency and reduce carrying costs.

In conclusion, streamlining inventory tracking systems through the adoption of advanced technologies and software solutions is paramount for optimizing warehouse management and achieving efficient logistics operations. By enhancing visibility, accuracy, and control over inventory, businesses can drive productivity, minimize costs, and ultimately deliver superior service to their customers.

Integrating Data Analytics for Enhanced Warehouse Efficiency

Integrating data analytics into warehouse management systems has become a crucial strategy for optimizing logistics operations. By harnessing the power of data, companies can gain valuable insights into their warehouse operations, leading to improved efficiency and cost savings.

One of the key benefits of integrating data analytics into warehouse management is the ability to track and analyze key performance indicators (KPIs) in real-time. With access to real-time data, warehouse managers can make informed decisions to streamline operations, reduce bottlenecks, and optimize inventory levels. By leveraging historical data, companies can also identify trends and patterns to forecast demand, leading to better inventory management and reduced stockouts.

Data analytics also plays a significant role in predictive maintenance, enabling warehouse managers to proactively identify equipment that requires maintenance, thus reducing downtime and enhancing overall operational efficiency. Furthermore, by analyzing data from various sources such as IoT devices and sensors, companies can optimize the layout of their warehouse, minimize travel distances, and improve the overall flow of goods.

Another critical aspect of integrating data analytics into warehouse management is the ability to enhance labor management. By analyzing data related to employee productivity, companies can identify opportunities for training and process improvement, leading to a more efficient workforce. Additionally, data-driven insights can help in optimizing picking routes and task allocation, further improving overall operational efficiency.

In conclusion, integrating data analytics into warehouse management systems is essential for companies looking to enhance efficiency and streamline their logistics operations. By leveraging the power of data, companies can make data-driven decisions, optimize warehouse processes, and ultimately gain a competitive edge in today’s dynamic business environment.