Implementing Automation in Warehouse Management Systems

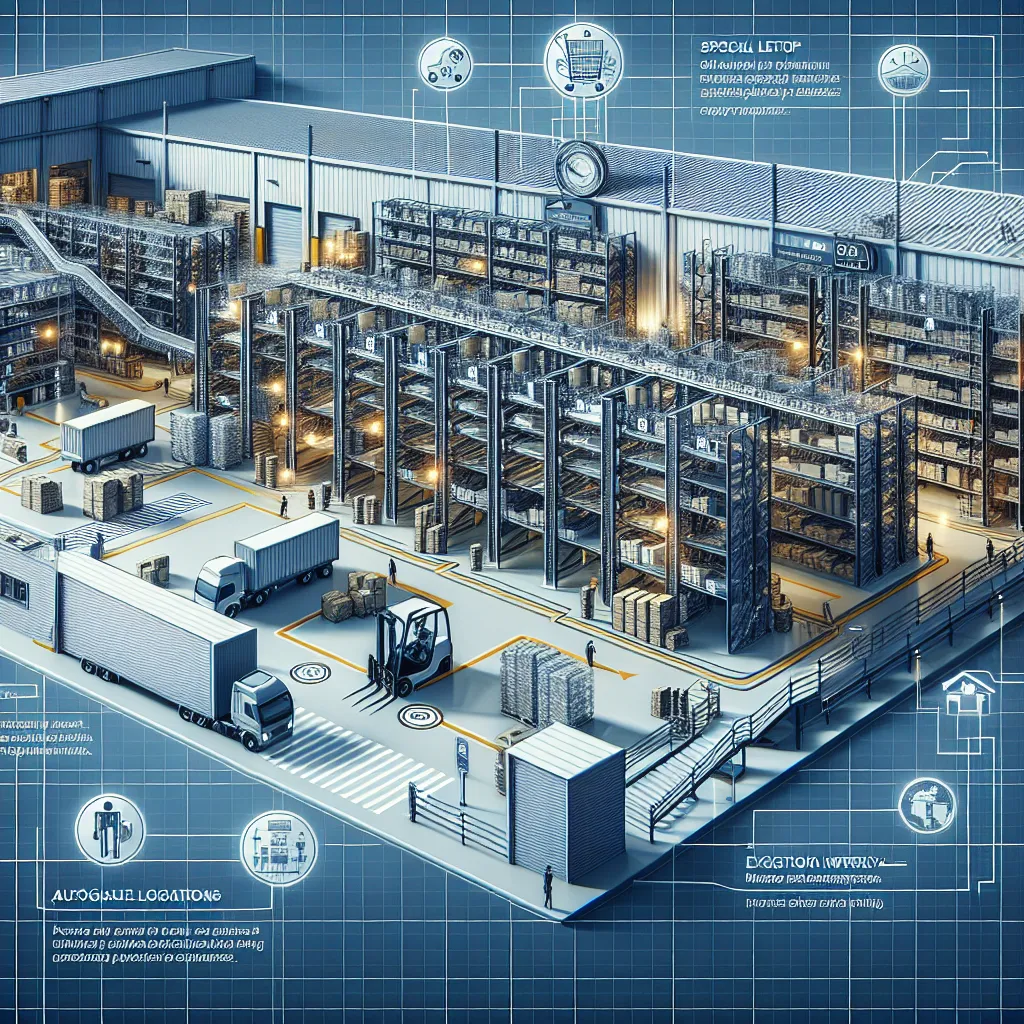

Implementing Automation in Warehouse Management Systems plays a crucial role in streamlining logistics processes. With the rapid advancement of technology, integrating automation into warehouse management has become increasingly essential for businesses looking to improve efficiency, accuracy, and overall performance.

One key aspect of implementing automation in warehouse management systems is the use of automated storage and retrieval systems (AS/RS). These systems utilize advanced technology such as robotics, conveyor systems, and computer-controlled mechanisms to automatically handle, store, and retrieve goods within the warehouse. By implementing AS/RS, businesses can significantly reduce the need for manual labor, minimize errors, and optimize space utilization within the warehouse.

Furthermore, automation in warehouse management systems allows for real-time tracking and monitoring of inventory levels, shipments, and order fulfillment. Advanced software and technology enable accurate and up-to-date data collection, providing valuable insights into the movement of goods and overall warehouse operations. This level of automation not only enhances visibility but also enables proactive decision-making to mitigate potential issues and improve overall efficiency.

In addition, the integration of automation in warehouse management systems can lead to significant cost savings in the long run. By minimizing human intervention and the associated errors, businesses can reduce labor costs, improve inventory accuracy, and optimize resource utilization. Moreover, automation enables warehouses to operate 24/7, leading to increased productivity and throughput.

In conclusion, implementing automation in warehouse management systems is key to streamlining logistics processes and staying competitive in today’s dynamic business environment. By leveraging advanced technology, businesses can achieve greater efficiency, accuracy, and cost savings while meeting the evolving demands of the market.

Implementing Automation in Warehouse Management Systems plays a crucial role in streamlining logistics processes. With the rapid advancement of technology, integrating automation into warehouse management has become increasingly essential for businesses looking to improve efficiency, accuracy, and overall performance.

One key aspect of implementing automation in warehouse management systems is the use of automated storage and retrieval systems (AS/RS). These systems utilize advanced technology such as robotics, conveyor systems, and computer-controlled mechanisms to automatically handle, store, and retrieve goods within the warehouse. By implementing AS/RS, businesses can significantly reduce the need for manual labor, minimize errors, and optimize space utilization within the warehouse.

Furthermore, automation in warehouse management systems allows for real-time tracking and monitoring of inventory levels, shipments, and order fulfillment. Advanced software and technology enable accurate and up-to-date data collection, providing valuable insights into the movement of goods and overall warehouse operations. This level of automation not only enhances visibility but also enables proactive decision-making to mitigate potential issues and improve overall efficiency.

In addition, the integration of automation in warehouse management systems can lead to significant cost savings in the long run. By minimizing human intervention and the associated errors, businesses can reduce labor costs, improve inventory accuracy, and optimize resource utilization. Moreover, automation enables warehouses to operate 24/7, leading to increased productivity and throughput.

In conclusion, implementing automation in warehouse management systems is key to streamlining logistics processes and staying competitive in today’s dynamic business environment. By leveraging advanced technology, businesses can achieve greater efficiency, accuracy, and cost savings while meeting the evolving demands of the market.

Utilizing IoT for Real-Time Tracking and Monitoring

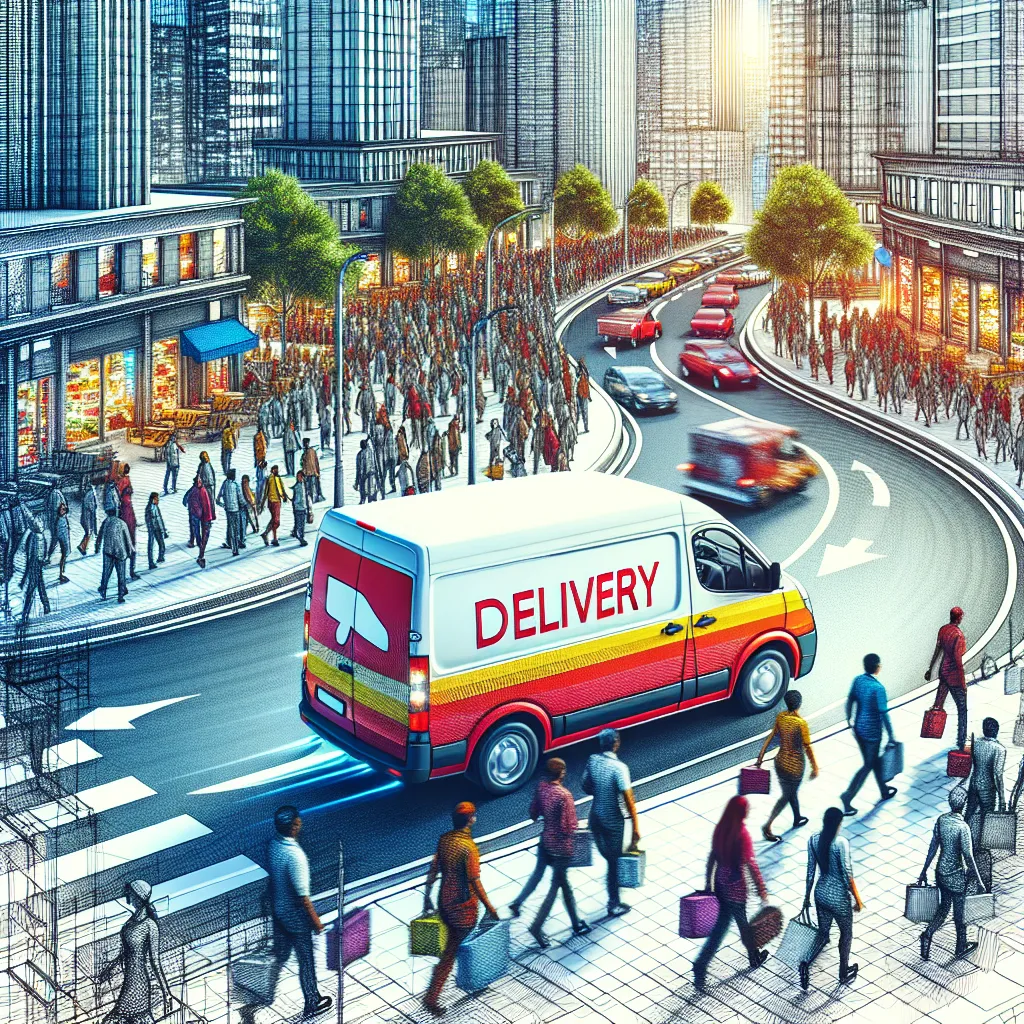

One of the pivotal aspects of streamlining logistics processes is the utilization of IoT for real-time tracking and monitoring. The integration of Internet of Things (IoT) technology in logistics operations has revolutionized the industry by providing unprecedented visibility and control over the entire supply chain. IoT enables companies to track the movement of assets, goods, and shipments at every stage of the logistics process, facilitating real-time monitoring of inventory levels, location tracking, and condition monitoring.

By leveraging IoT devices such as GPS trackers, RFID tags, and sensors, logistics companies can gather valuable data and insights that enable them to optimize routes, minimize delays, and enhance overall operational efficiency. Real-time tracking and monitoring capabilities offered by IoT solutions empower logistics managers to proactively address potential issues, such as route deviations, unforeseen delays, or inventory discrepancies, before they escalate into larger problems.

The seamless integration of IoT technology with logistics processes also facilitates the implementation of predictive maintenance strategies, as sensors can detect potential equipment failures or malfunctions in real time, allowing for timely interventions to prevent costly downtime or disruptions in the supply chain. Additionally, IoT-enabled real-time monitoring enhances security measures by providing continuous surveillance of goods in transit, reducing the risks of theft, damage, or tampering.

In conclusion, the adoption of IoT for real-time tracking and monitoring is a game-changer in the logistics industry, offering unparalleled visibility, efficiency, and control over supply chain operations. With IoT-driven insights and actionable data, logistics companies can optimize their processes, reduce costs, and deliver superior customer experiences.

Optimizing Supply Chain with AI and Machine Learning

Technology has been playing a crucial role in streamlining logistics processes, and one of the key aspects of this transformation is the optimization of the supply chain using artificial intelligence (AI) and machine learning. AI and machine learning algorithms have the potential to revolutionize the way supply chains operate by optimizing processes, improving efficiency, and reducing costs.

AI and machine learning technologies can analyze large volumes of data to identify patterns, predict demand, and optimize inventory levels. By leveraging predictive analytics, supply chain managers can make more informed decisions, anticipate potential disruptions, and ensure that the right amount of product is available at the right time and place. This proactive approach minimizes excess inventory and stockouts, leading to cost savings and improved customer satisfaction.

Furthermore, AI and machine learning can enhance route optimization and fleet management. These technologies can process real-time data on factors such as traffic, weather, and road conditions to recommend the most efficient delivery routes, reducing fuel consumption and transportation costs. Additionally, predictive maintenance enabled by AI can help prevent equipment failures, minimizing downtime and optimizing the utilization of assets.

In conclusion, the integration of AI and machine learning in supply chain operations offers significant opportunities for optimization. By harnessing the power of these advanced technologies, businesses can streamline logistics processes, improve efficiency, and ultimately gain a competitive edge in today’s dynamic marketplace.